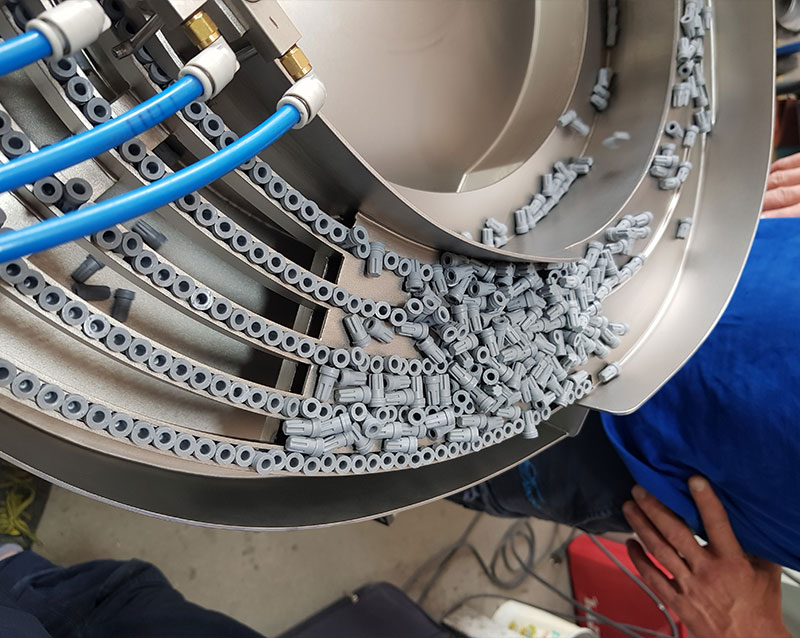

Multi-line vibrating system for rubber pistons

Customized solutions for processing bungs on 8 paths A thorough evaluation ensures item integrity. If specified by the customer, the selection involves continuous seams and offcuts to enable any excess powder to escape. The system can be supplemented by a combined loading hopper that can vary according to the required autonomy, the plant consisting of a support structure, noise-damping protection and control panel that makes the machine a turnkey project. Recommended for production rates up to 12000 items an hour.

Vibrating system for Flip Off caps

Years of consolidated experience have enabled us to present our solution for processing this type of item. At guaranteed speeds of 50 items a minute, several models can be processed with the same format. If for technical reasons this is not possible, owing to rapid format changes it is also possible to process many different models. With the due precautions, the integrity of the item is guaranteed, offering a compact and functional solution. The combined loading hopper that can vary according to the required autonomy, and the plant consisting of a vibrating channel, support structure, noise damping protection and control panel make the machine a turnkey project.

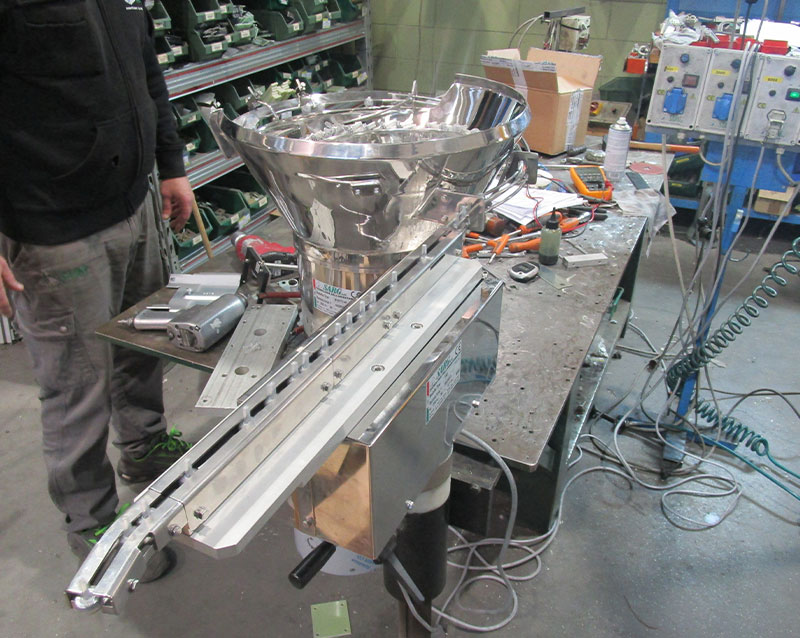

System for mini tulip pharmaceutical caps

Customized system for processing caps at low/medium production speeds. Precise technical customization enables several formats to be processed with the same plant. Unit meeting pharmaceutical industry specifications with a solution that ensures production speeds up to 50 caps a minute. The system can be supplied with a loading hopper, support bench and a noise-damping protection.

Multi-line vibrating system for bungs

Customized solution for bungs for pharmaceutical industry. Simple adjustments enable different models to be processed with customized formats With the due precautions, the integrity of the bung is guaranteed, offering a compact and functional solution. Depending on customer requirements, the plant can be supplied in configurations from 1 to 4 paths. The combined loading hopper that can vary according to the required autonomy, and the plant consisting of a vibrating channel, support structure, noise-damping protection and control panel make the machine a turnkey project. Recommended for production rates up to 50 bungs a minute.

Vibrating system for ring nuts

We suggest our standard solution for processing most of the collars currently on the market. At guaranteed speeds of 200 items a minute, several models can be processed with the same format. Experience garnered over the years allows us to supply the vibrator in different orientation versions that are tailored to the needs of the end consumer.