CI and TC bowl feeders

SARG designs and manufactures various types of vibratory drives, assisted by cylindrical (CI) and conical (TC) bowl feeders, depending on the specific usage requirements.

Recommended for slower speeds and smooth handling (as opposed to solutions with mechanical and/or centrifugal orienters), vibratory systems with cylindrical and conical bowl feeders allow for processing most of the parts currently on the market where automation systems are needed and increase profitability.

Our vibratory systems with cylindrical and conical bowl feeders are customized for the specific industry application and conform to the relative industrial codes (pharmaceutical, food, cosmetics, etc.).

We deliver standard feeding systems or specific solutions for unstable components or parts with particular configurations. For specific information about the vibratory orienters with cylindrical and conical bowl feeders we produce, consult the individual technical sheets or contact us for further clarification.

Bowl feeders for vibratory systems: applications and solutions

Vibratory systems require a specific conical or cylindrical parts-orienting bowl feeders, intended to collect and to align correctly the oriented parts. These systems are suitable for various applications and are suitable for the treatment of lightweight (such as moulded plastic items), aluminium or metallic parts.

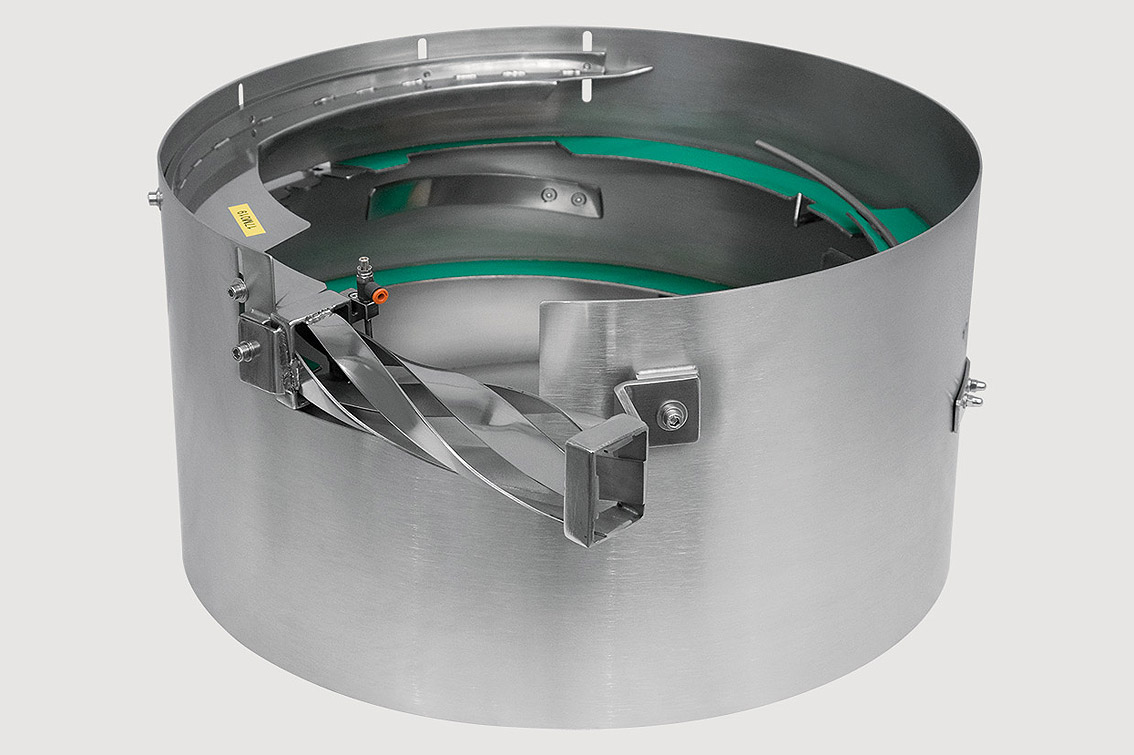

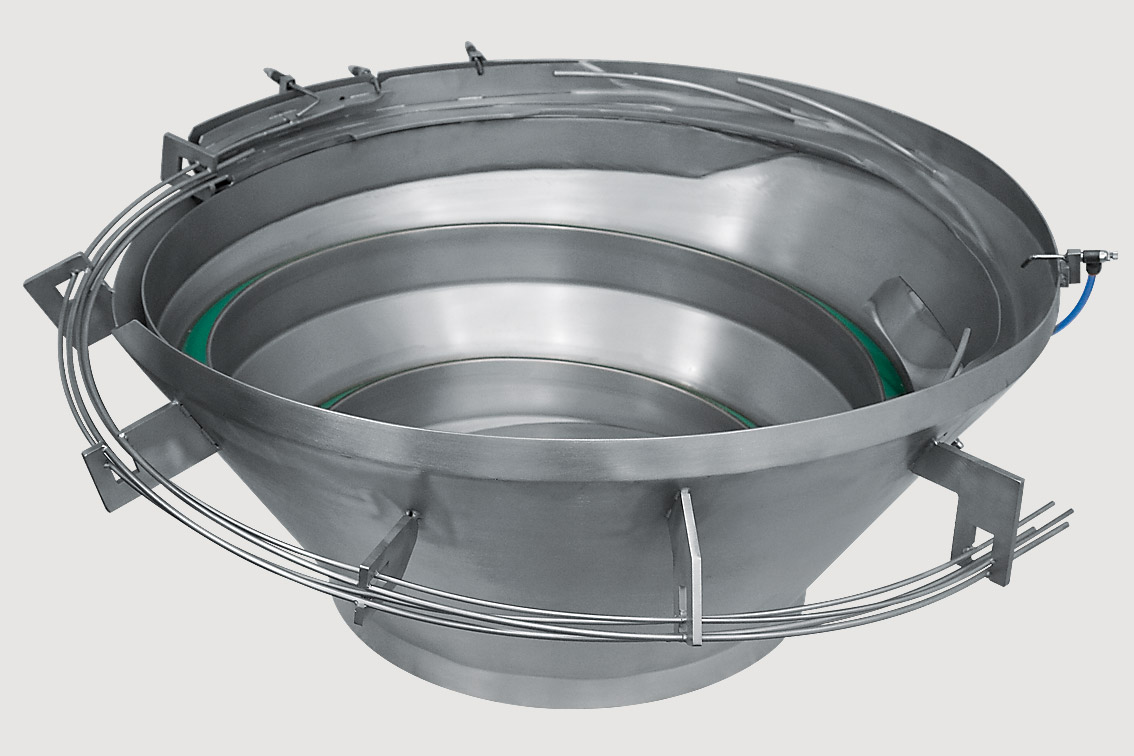

Our cylindrical and conical bowl feeders are built with an internal spiral track, designed to collect parts and facilitate their ascending flow, thus allowing the advancement to the production process. The internal structure of the bowl feeders is designed to prevent damage to the parts and feed them smoothly in a energy efficient manner.

CI cylindrical bowl feeders are particularly suitable for a variety of applications, from aluminum capsules to other plastic containers for cosmetics, from coffee capsules to trigger pumps, from metal crown corks to plastic caps or lids. This type of bowl feeder adapts to our vibrating drive units.

TC conical bowl feeders, on the other hand, are a particularly suitable solution for use in the cosmetic or pharmaceutical industry, ideal for hand pumps, nebulizers, perfume vaporizers, syringes, dispensers, vials, cosmetic jars, pipettes and pipettes dispensers.

All CI and TC bowl feeders is subjected to different surface treatments depending on the needs, such as glas blead blasting , polishing or passivation. For a smooth handling handling of the parts, different track coating like e.g. PU can be used. Contact us and tell us about your projects: we will study the solution best suited to your needs together.