Rotary mechanical or centrifugal feeding devices and compact industrial feeding systems for every need.

Sometimes these feeders are also referred as Centrifugal Sorter, Unscrambler, Rotary Orientor)

SARG designs and manufactures different types of centrifugal feeding devices, with 3 different technologies based on their use.

SARG’s centrifugal feeders are specifically designed for gentle parts handling, easy and quick format changeover, reliability, and efficiency. Our proficiency and experience allow us to handle complex applications effectively at high rates of speed. Usage of proven tooling practices for the orientation of the feeding goods, reduces downtime and guarantees constant high productivity.

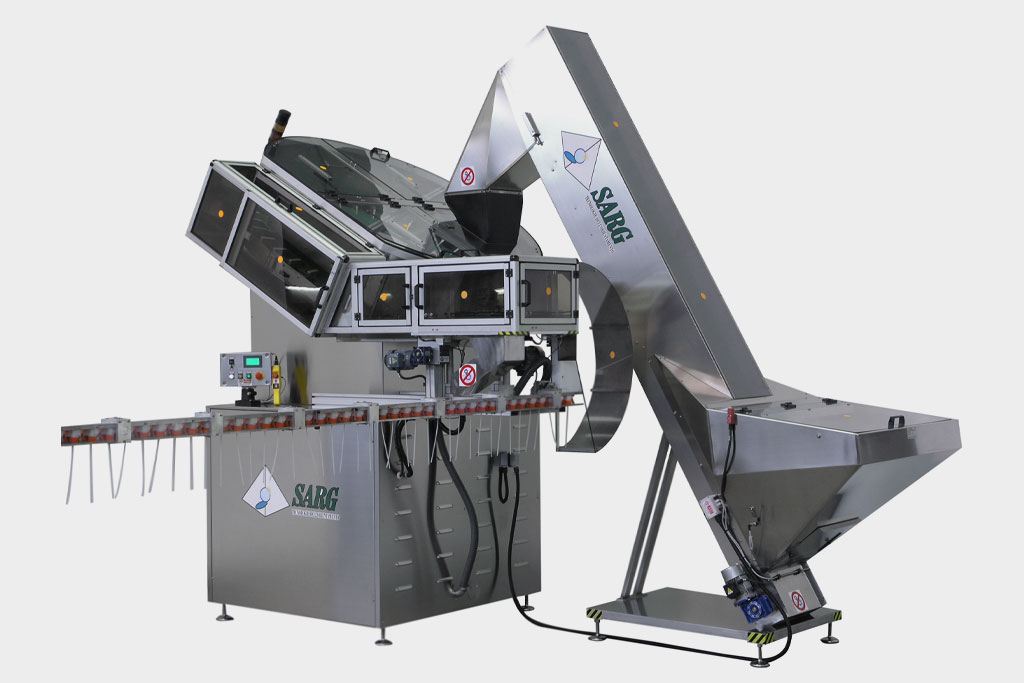

Centrifugal feeders with Form-Fit (referred also to Scallop or Puck-Feeders)

Used for high-speed applications (unlike classic vibratory solutions), SARG STM centrifugal feeders enable processing of various types of products (bottles, triggers, dispensers, aerosol valves with/without suction, closures, etc.) at the highest output and have been proven in more than 2.000 high speed applications.

SARG STM Sorter are long-time proven systems, optimized for applications like filling and packaging according to the needs of each industry (pharmaceutical, food, cleaning and personal care, cosmetics, etc.) and therefore deliver stable and high performance.

SARG has a range of 9 sizes from STM068 to STM250 to feed your parts efficiently and economically. Moreover, for dispensers, hand pumps, nozzle pumps and trigger pumps, we have developed exclusive solutions to feed these complex parts safely and gently up to 250 pumps per minute.

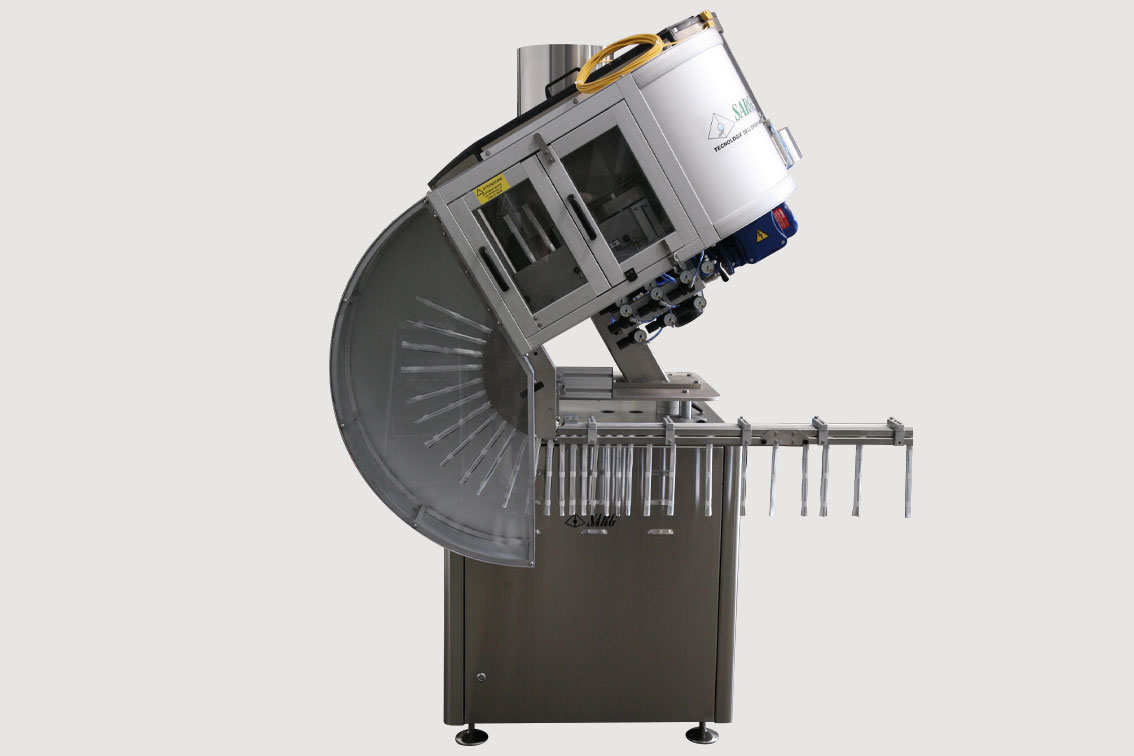

Centrifugal feeders

As a result of our long-standing experience, we deliver compact systems that guarantees maximum performance in solutions where high speed must be a constant.

Our systems are specially optimized for the pharmaceutical, food, cosmetics industries. Centrifugal feeders are also often used in the coffee industry for feeding filters for the capsules assembly, coffee capsules for filing and packaging of filled capsules.

We develop both standardized and specific solutions for complex components or with special requirements. Our standard range in STC orientation is covering 4 sizes: from STC058 to STC120 up to 4.000 parts per minute.

For more precise information on our centrifugal feeding systems, please refer to the individual data sheets or contact us for further details.