The industrial feeding sector is characterised by a multiplicity of applications, each of which requires preliminary studies and a great deal of expertise to create tailor-made solutions. SARG is the specialist for the development and implementation of customized feeding solutions for coffee capsule and K-Cups. Take advantage of the know-how of a leading company in this field to also find the best and most reliable solution for you in this important application area. We have a wide range of solutions and will be happy to help you.

ASSEMBLY solutions

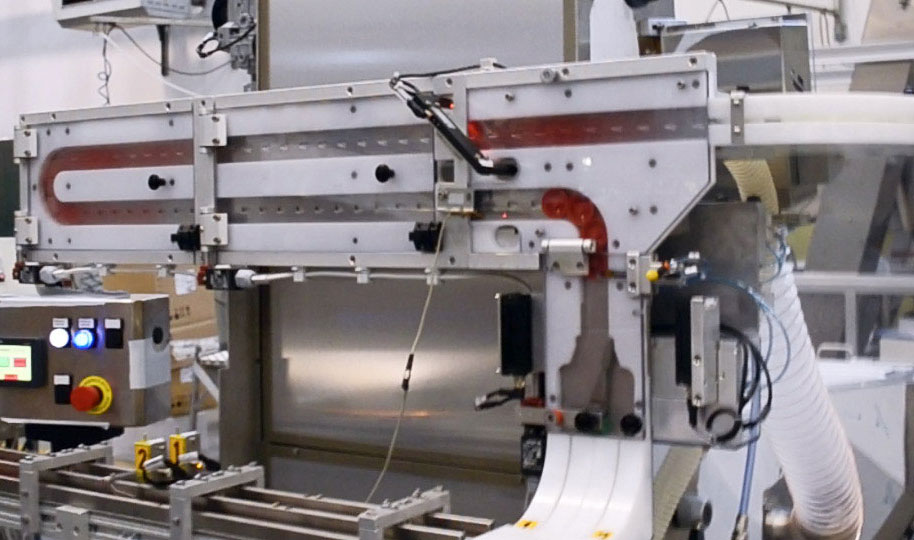

SARG delivers systems suitable for processing all components required for the assembly of coffee capsules o K-Cups (capsules, filter systems, creamer discs, etc). We design machinery suitable for high production rates and offer solutions that can be customised based on the OEM or coffee producer’s needs. Our range of solutions is composed of a loading lifter, accumulation tracks, support structure and electrical management panel.

The industrial feeding sector is characterised by a multiplicity of applications, each of which requires preliminary studies and a great deal of expertise to create tailor-made solutions. SARG is the specialist for the development and implementation of customized feeding solutions for coffee capsule and K-Cups. Take advantage of the know-how of a leading company in this field to also find the best and most reliable solution for you in this important application area. We have a wide range of solutions and will be happy to help you.

ASSEMBLY solutions

SARG delivers systems suitable for processing all components required for the assembly of coffee capsules o K-Cups (capsules, filter systems, creamer discs, etc). We design machinery suitable for high production rates and offer solutions that can be customised based on the OEM or coffee producer’s needs. Our range of solutions is composed of a loading lifter, accumulation tracks, support structure and electrical management panel.

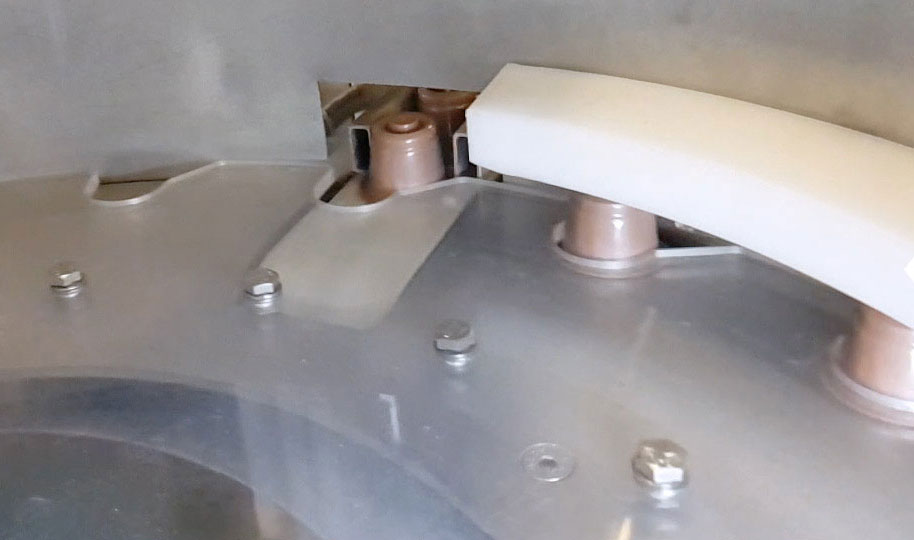

QUALITY CONTROL solutions

In collaboration with the best technologies currently on the market, SARG offers high-speed solutions with the implementation of vision systems that allow the detection of any imperfections or non-conformities on the capsule or filter discs. Our coffee capsule feeder can process most types of capsules: self-protected or not, and in different types of thermoplastic, compostable or biodegradable materials.

SINGLE AND MULTI-LINE CAPSULE FILLING solutions

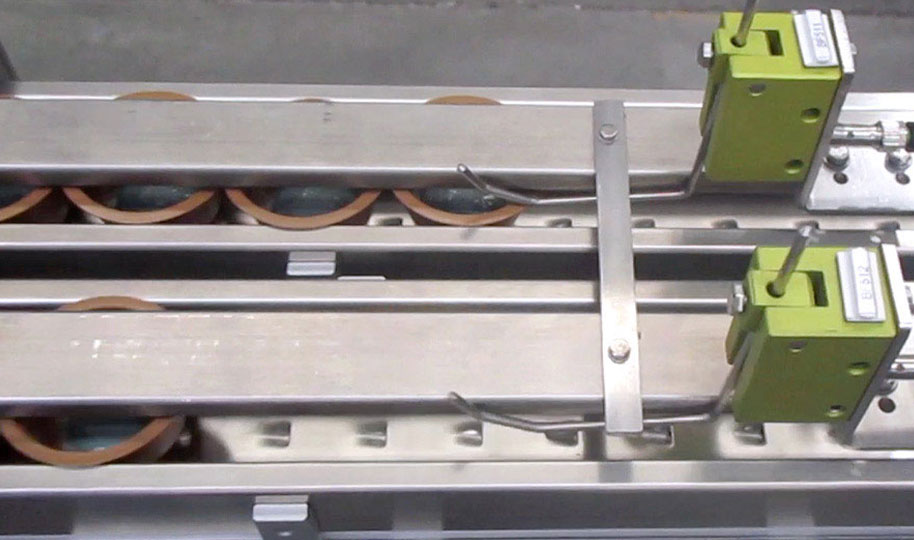

We are focused on the capsule filling process providing a wide range of systems that vary according to the speed required by the customer on 1 up to 16 tracks up to 1.500 capsules per minute. The solutions we have designed can unscramble and feed the majority of coffee capsules and K-Cups and are fit in solutions for all kind of coffee capsules filling machines

CAPSULE PACKAGING solutions

SARG proposes systems that process filled capsules and K-Cups, guaranteeing their integrity while working at high speed. Thanks to the experience gained over the years, we are building different solutions depending on the speed and type of coffee capsule.

For any further information on our capsule orientator or on our coffee capsule systems, please contact us without obligation.

QUALITY CONTROL solutions

In collaboration with the best technologies currently on the market, SARG offers high-speed solutions with the implementation of vision systems that allow the detection of any imperfections or non-conformities on the capsule or filter discs. Our coffee capsule feeder can process most types of capsules: self-protected or not, and in different types of thermoplastic, compostable or biodegradable materials.

SINGLE AND MULTI-LINE CAPSULE FILLING solutions

We are focused on the capsule filling process providing a wide range of systems that vary according to the speed required by the customer on 1 up to 16 tracks up to 1.500 capsules per minute. The solutions we have designed can unscramble and feed the majority of coffee capsules and K-Cups and are fit in solutions for all kind of coffee capsules filling machines

CAPSULE PACKAGING solutions

SARG proposes systems that process filled capsules and K-Cups, guaranteeing their integrity while working at high speed. Thanks to the experience gained over the years, we are building different solutions depending on the speed and type of coffee capsule.

For any further information on our capsule orientator or on our coffee capsule systems, please contact us without obligation.

Coffee capsule feeders and capsule filling machines

Coffee capsule feeders are a crucial component in coffee manufacturing. These feeders are used to provide solutions for coffee capsule filling machines, allowing for efficient and streamlined production of coffee capsules. These machines are commonly used in commercial settings, such as coffee roasters and factories, to improve the speed and efficiency of the capsule-filling process.

The way a coffee capsule feeder works is to align the capsules in 1 or up 16 rows to feed to the machine for automatically filling capsules with a pre-measured amount of coffee grounds. The coffee grounds are stored in a hopper, which feeds the grounds into the capsule filling machine. The filling machine then uses a series of mechanical components to compress the grounds and seal the capsule. The capsules are put in prefeeders which feed the mechanical orientors / centrifugal feeder in constant way to keep the capsule flow via the feeder to the filling machine on the desired high and efficient level.

Coffee capsule feeders improve speed and reliability

Coffee capsule feeders are generally used in automated assembly solutions for the coffee capsule industry, in the filling process or in the packing process for filled capsules. These feeders can be integrated into existing assembly lines to provide a seamless and automated process for the assembly coffee capsules (capsule and filters). This not only increases productivity, reducing the need for manual labor and increasing efficiency, but also ensures consistency and accuracy in the final product.

As a matter of fact, coffee capsule feeders can be used in the process to fill and seal hundreds (up to 1.600) of capsules per minute. Additionally, coffee capsule feeders are highly precise and reliable. Downstream the filling machines which means are guaranteeing that the amount of coffee grounds used in each capsule is consistent and accurate. This improves the reliability of the finished product, as the coffee in each capsule will be of a consistent strength and quality.

Coffee capsule feeders are also designed for easy maintenance, which means that they can continue to operate with minimal interruption. They are easy to clean and maintain, and can be quickly serviced if there are any issues. This helps to minimize downtime and ensure that the production process runs smoothly.

Coffee capsule feeders are a key component in the coffee industry for industrial use, providing solutions for coffee capsule filling machines and facilitating automation and assembly in the coffee production process. The can be used for all types of capsules, like K-cups, compatible Nespresso caps, A Modo Mio, different Lavazza types, etc, only to name a few ones out of many different existing capsules.