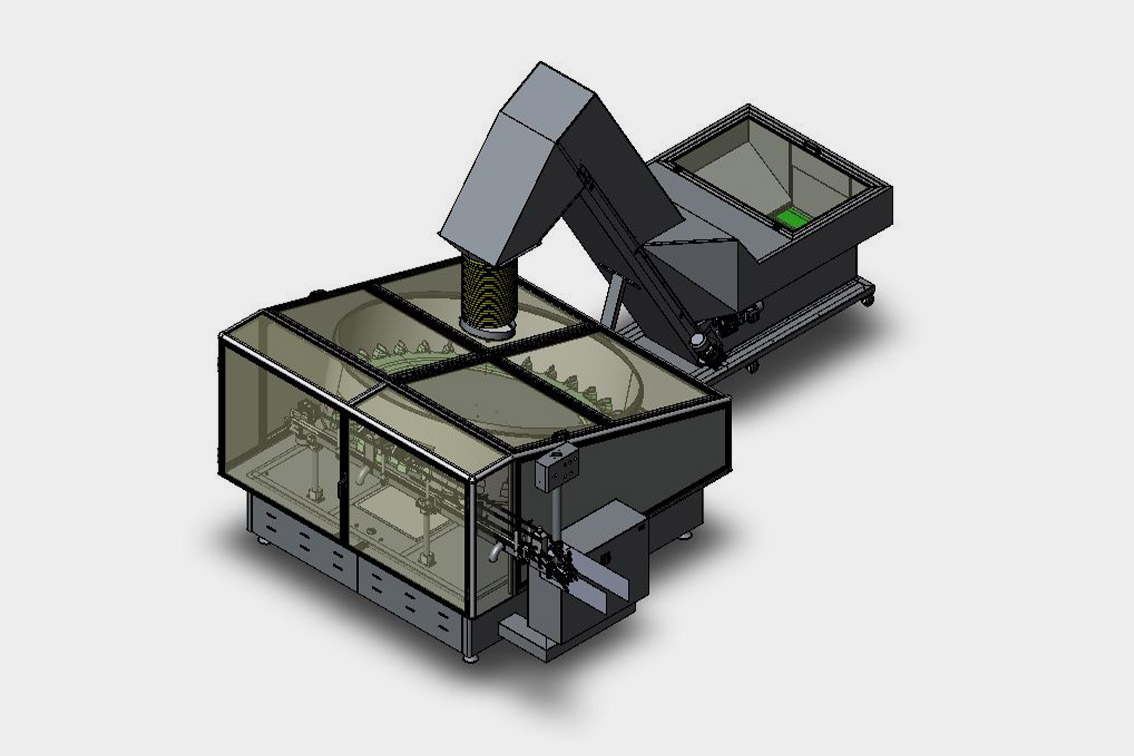

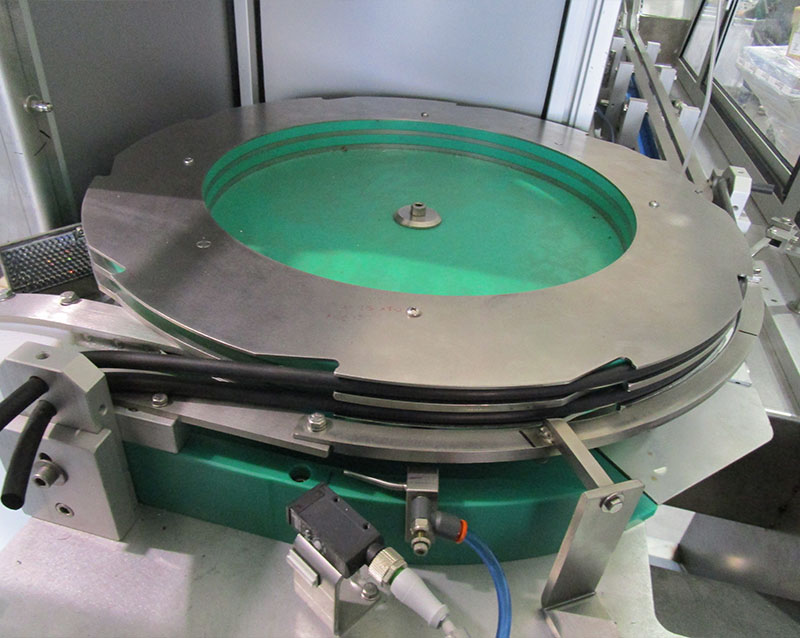

Solution for orienting single or composite caps for detergents/softeners

Customized system for processing caps at high production speeds. Rapid adjustments and customized format changes enable several models to be processed with the same plant. Unit designed for the specific needs of the home care industry. On request, a guard can be supplied to reduce noise. Quick-release clips can be fitted to make format changing easier. For high production speeds, we propose a Sarg standard that is the fruit of years of experience.

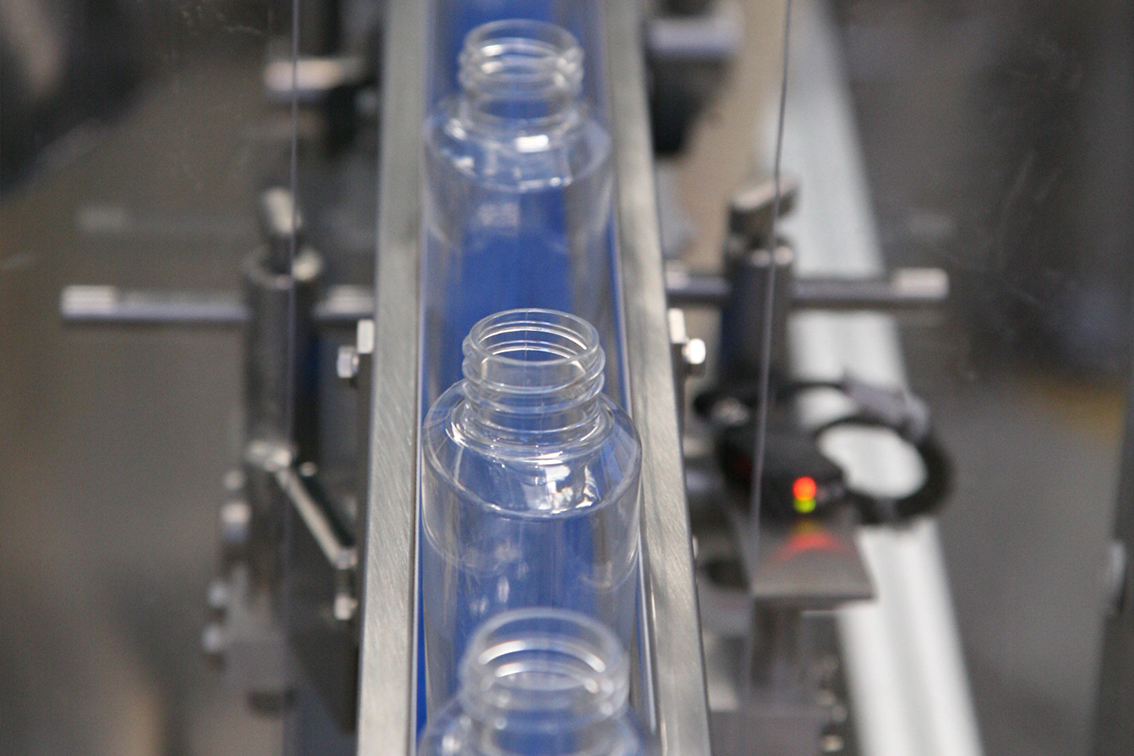

Mechanical orientator for bottles

Sarg solution that enables bottles of different dimensions and materials to be processed. The orientator’s customized support structure combined with a suction belt ensures a high-performance solution with reduced consumption and performance up to 100 items a minute. The customized format changes enable several formats with different dimensions to be processed by the same plant. The system is provided with a soundproofing protection to reduce noise.

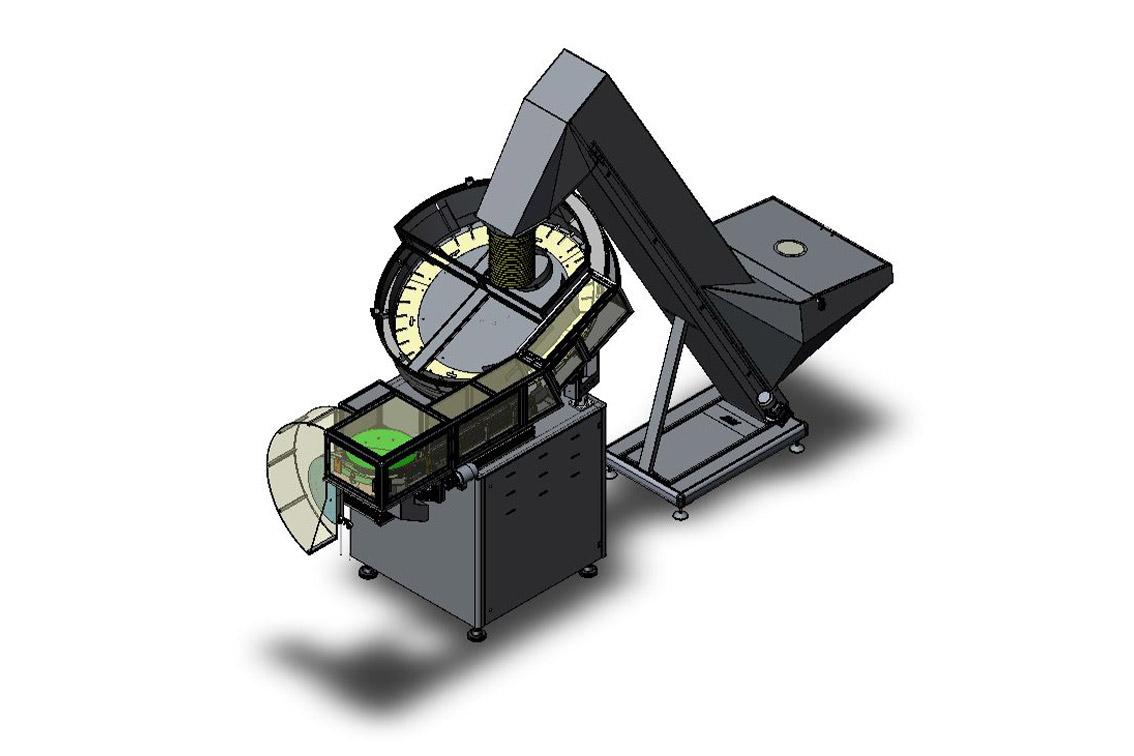

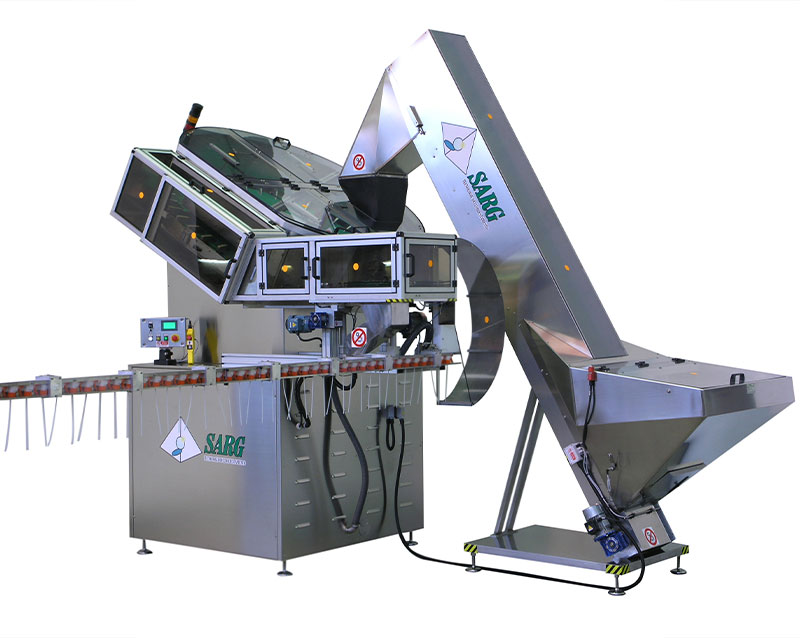

Mechanical orientator for triggers

Customized system for processing most triggers at 100 items a minute. With the appropriate precautions, the system enables the items to be so processed that they are ready for capping by interfacing with the customer’s machine. Customized adjustments and format changes enable different models to be processed with the same machine. The combined loading hopper that can vary according to the required autonomy, and the plant consisting of an air channel, a support structure, noise damping protection and control panel make the machine a turnkey project.