SARG manufactures industrial prefeeders, bulk elevators and loading hoppers to ensure that the main feeding system is constantly loaded with parts to be processed, based on customer requirements.

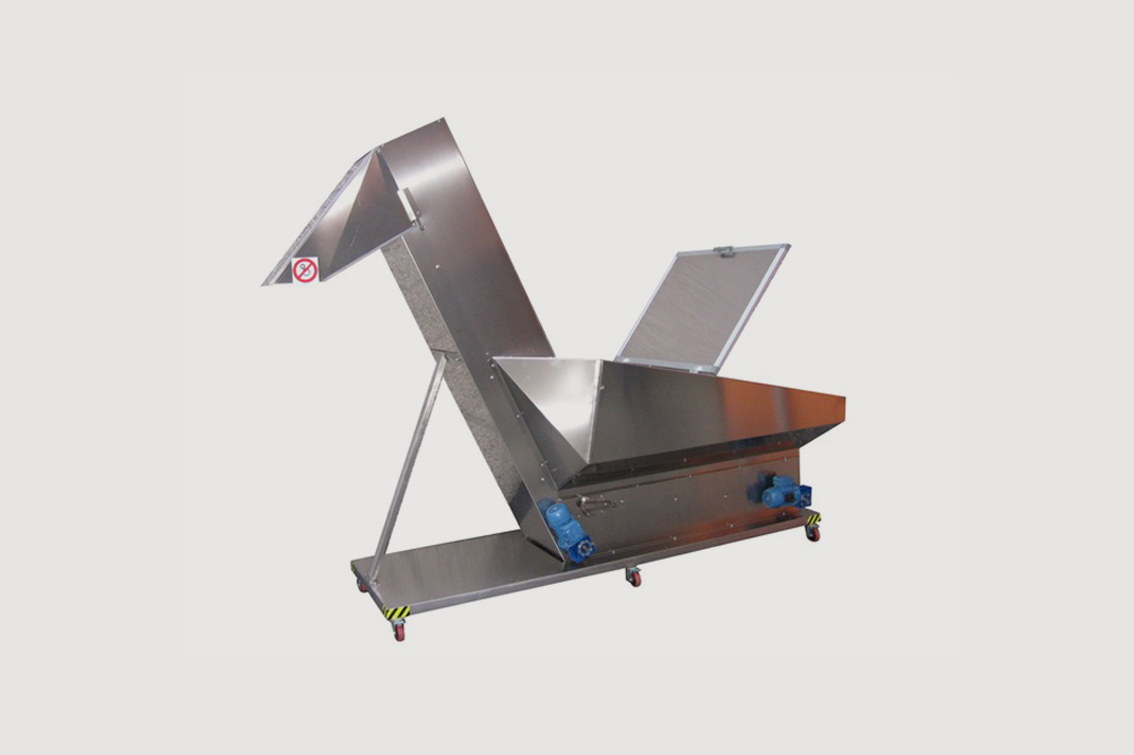

The elevator consists of a ground loading hopper, an ascending belt and an unloading gravity chute to convey the parts inside the feeder.

We deliver different types of elevators: from standard ENF bulk elevators, pneumatic elevators for caps, capsules and, to inclined or vertical belt elevators for caps, bottles and special designed elevators for such parts like triggers, dispensers, hand pumps, spray pump with long dip tubes.

Focused for the beverage sector: Cap sorting elevators “waterfall cap sorter” using the gravity to assure the correct cap feeding

Standard 304 Stainless steel construction makes SARG Elevators durable and reliable pre-feeders. They make a visible difference in the performance of your feeding system

For further information, please refer to the data sheets of the individual models or contact us for more details.

Vibratory prefeeder hoppers and belt hoppers

Hoppers are usually mounted on the same structure as the feeding unit.

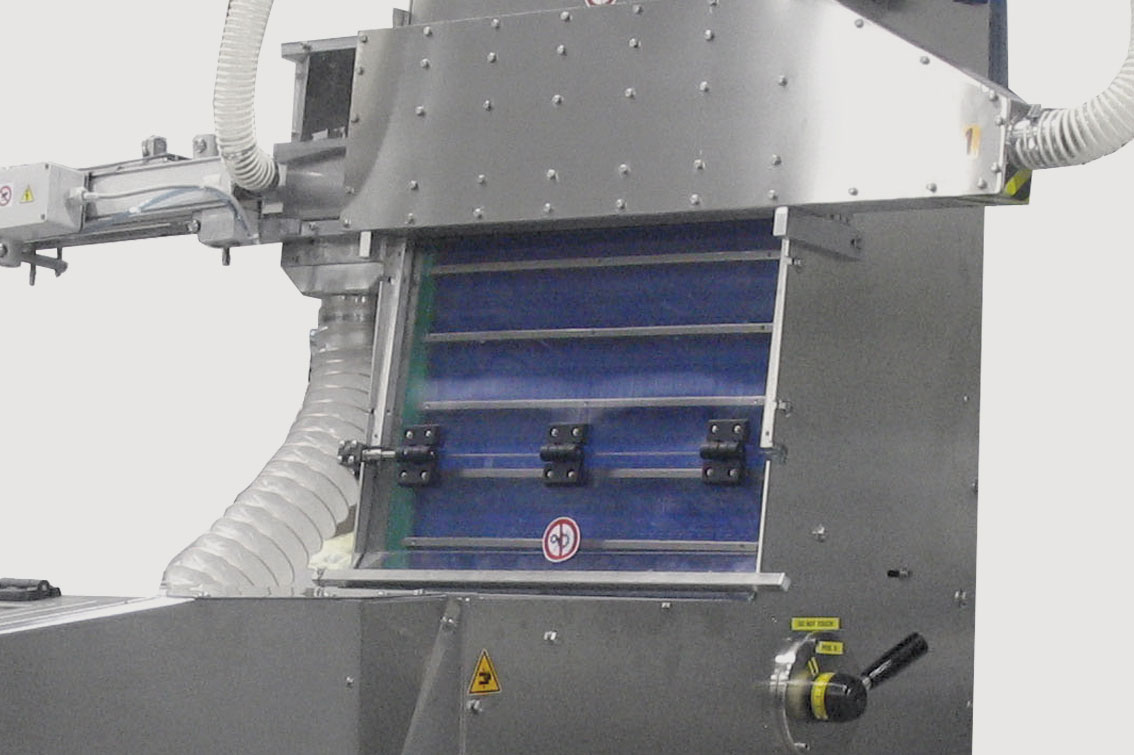

SARG is specialized in hoppers, covering different loading capacities according to the needs indicated by the customer and the production speed of the machine on which they are to be fitted. To cover the needs of our application segments we manufacture motorised belt hoppers (TRTI / TN) or line hoppers, hoppers with a linear vibrator (vibrating hoppers).

Vibratory Hopper prefeeders – vibrators for hoppers

vibratory hopper feeders are excellent for small parts. Vibrators have the function of preventing clogging of the loading system due to the shape or friction coefficient of the parts. A properly tuned hopper makes the difference when it comes optimizing the feeder system to a perfect operation. A hopper decreases the frequency of operators loading new parts and is used to regulate the part levels in the bowl so that orienting and sorting features inside the bowls work optimally. They speed can be adjusted to the parts flow.

If you have any specific requirements, please contact us without obligation and we will provide you with all relevant information.