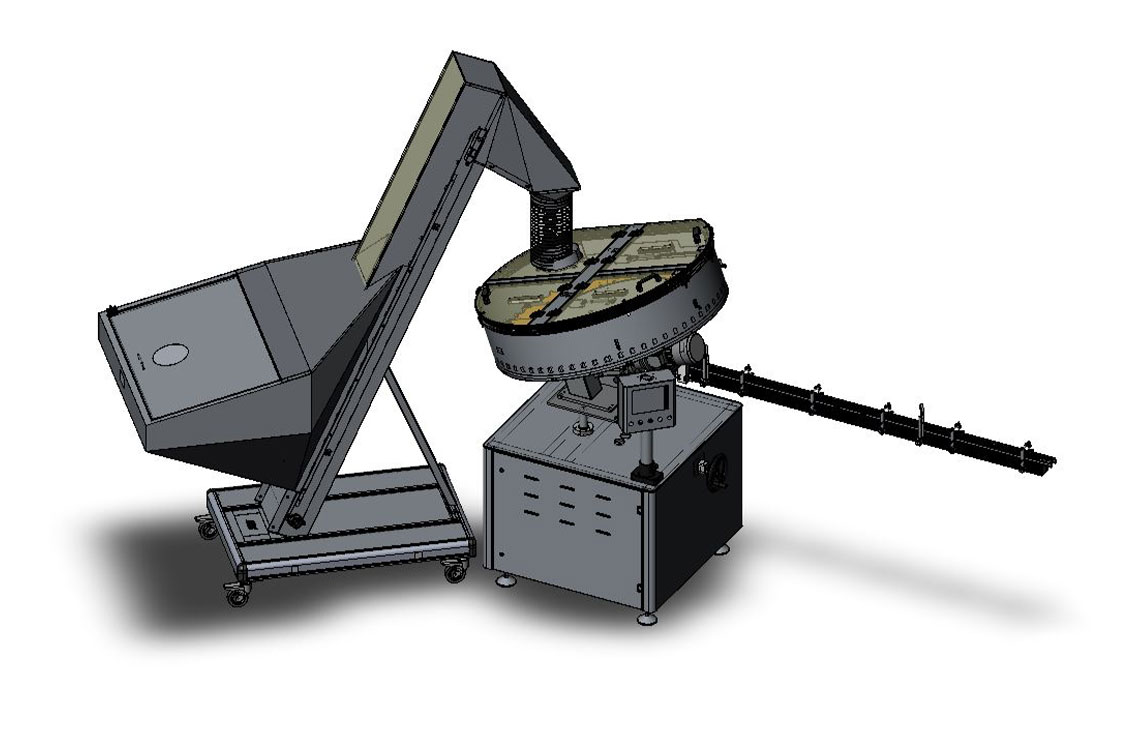

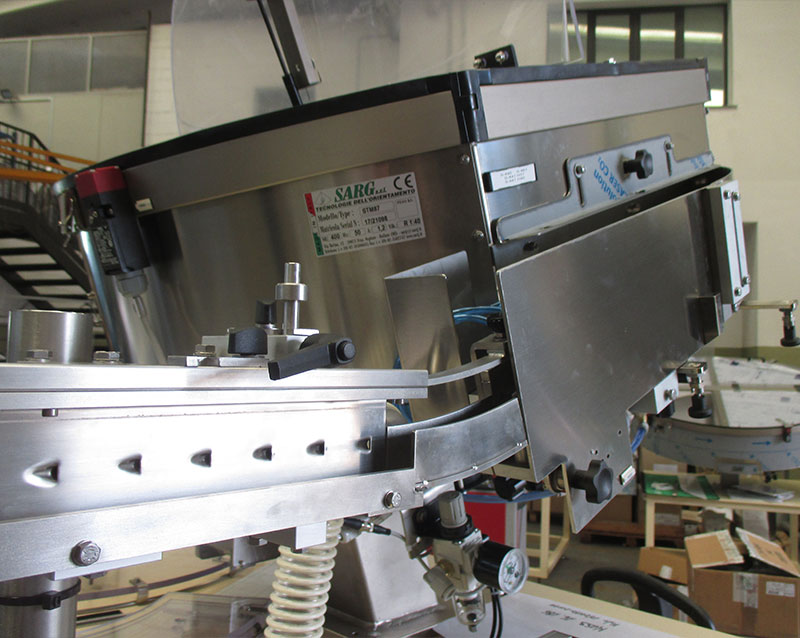

Mechanical orientator for caps

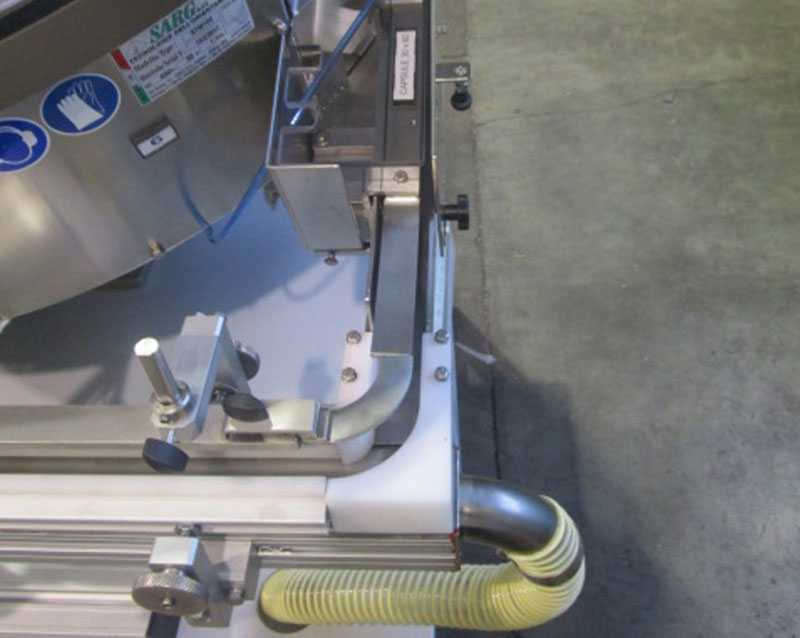

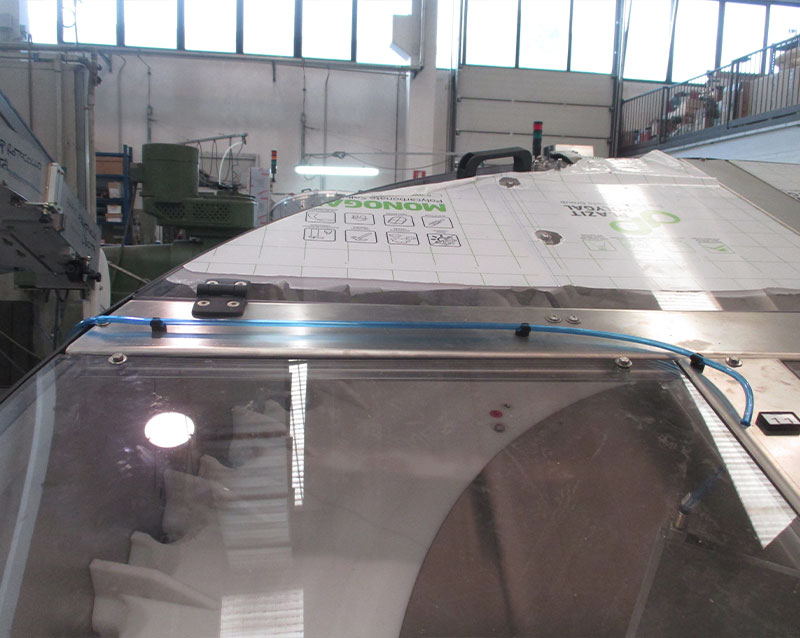

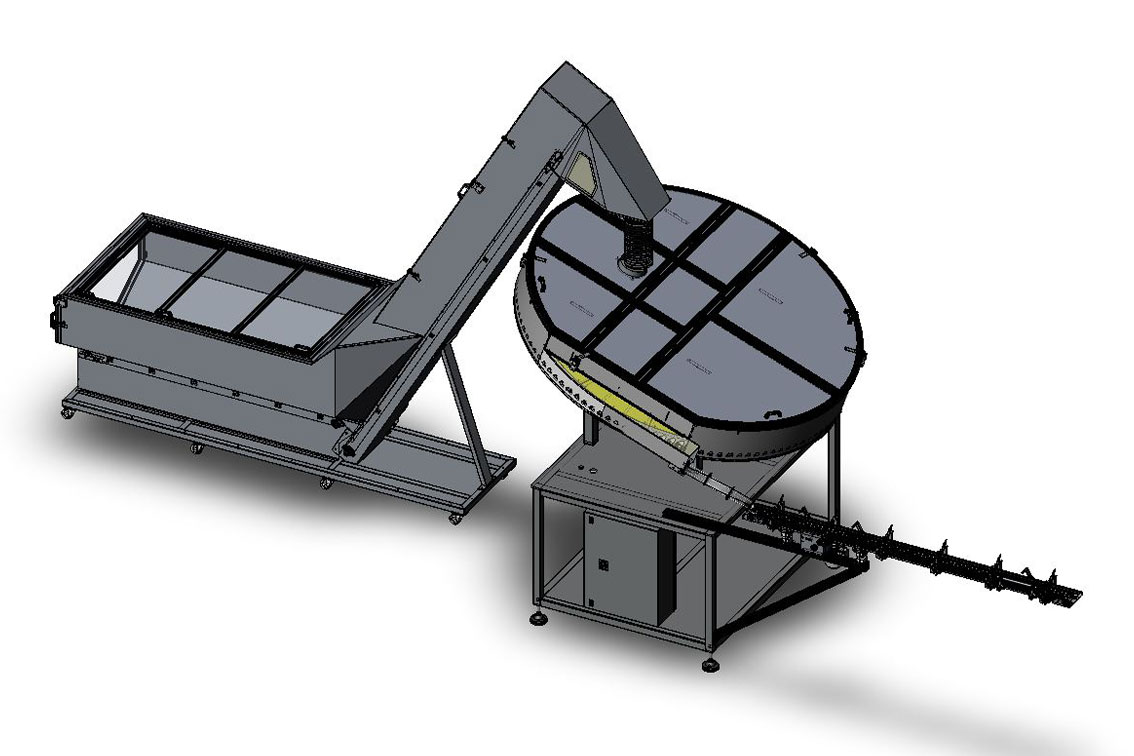

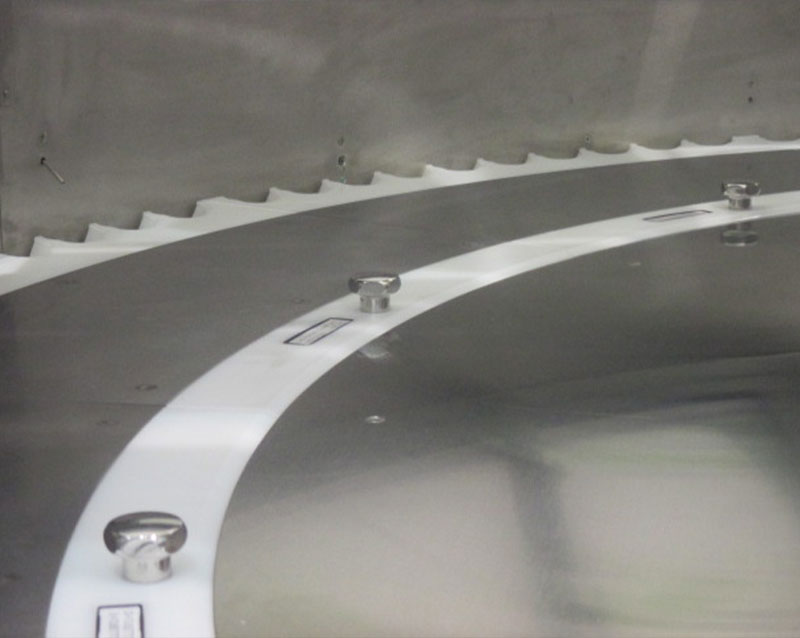

Owing to the experience garnered over the years, we are able to present our standard solution for processing most of the aluminium/plastic caps that are currently available on the market. At guaranteed speeds that vary according to the diameter of the orientator, several models can be processed with the same format. With the due precautions, the integrity of the item is guaranteed, offering a compact and functional solution. The combined loading hopper that can vary according to the required autonomy, and the plant consisting of an adjustable channel, support structure, noise damping protection if required and control panel make the machine a turnkey project.

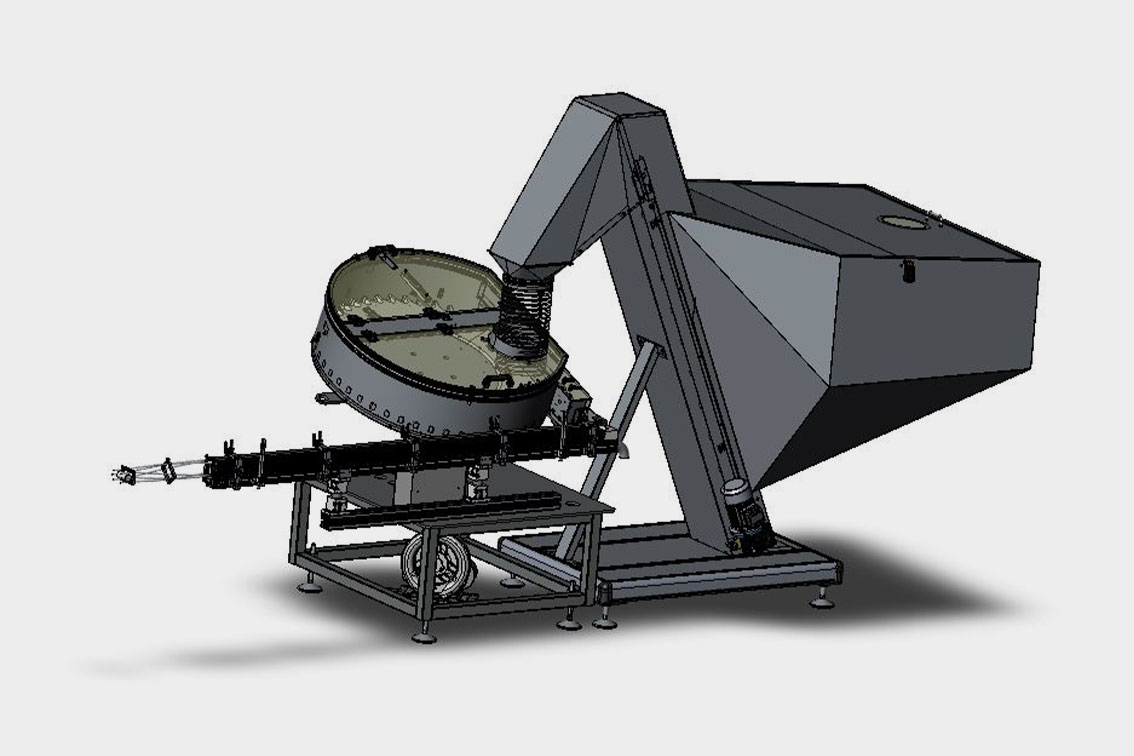

Mechanical orientator for flaming

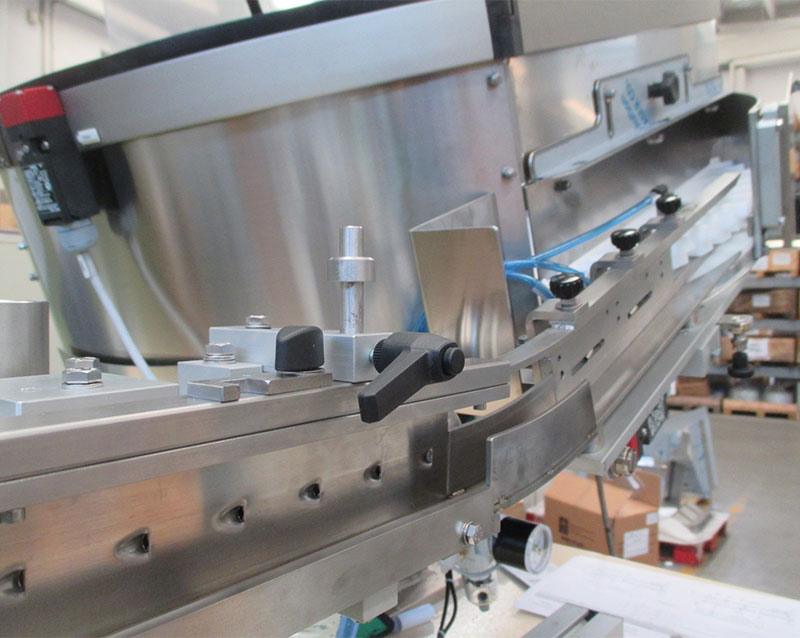

Customized system for processing caps at 200 items a minute. With the due precautions, the machine enables the integrity of the items being processed to be guaranteed. Customized conveying systems ensure that the items are processed in a single position. The customized format changes enable different models to be processed with the same plant. The combined loading hopper that can vary according to the required autonomy, and the plant consisting of an air channel, a support structure, noise damping protection and control panel make the machine a turnkey project.

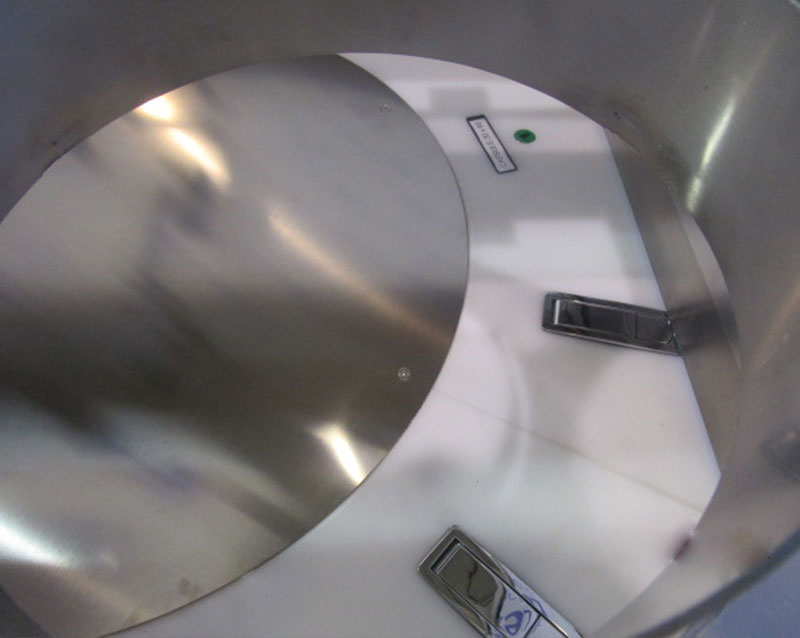

Mechanical orientator for lipstick caps and mechanisms

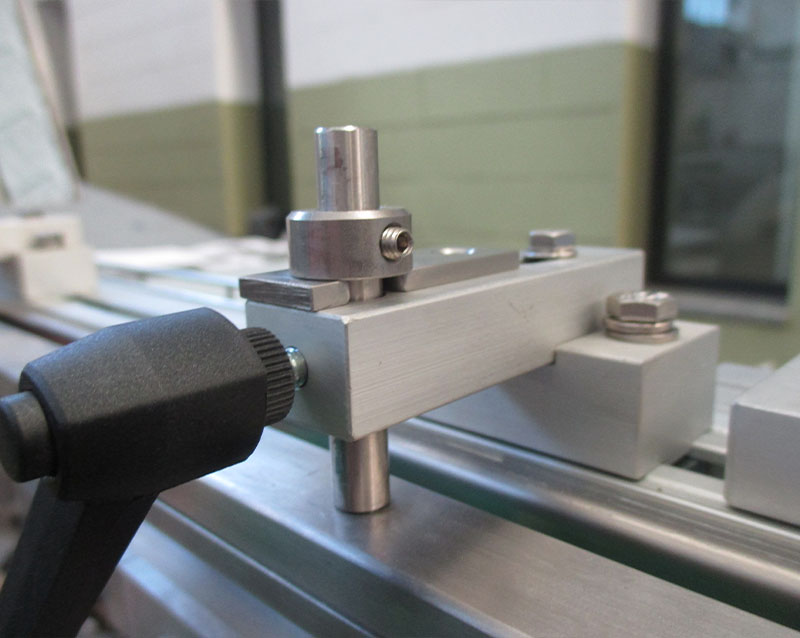

Sarg solution that enables plastic items of different dimensions and materials to be processed. The orientator’s customized support structure combined with an air channel ensures a high-performance solution with reduced consumption and production rates up to 250 items a minute. The customized format changes enable several formats with different dimensions to be processed by the same plant.

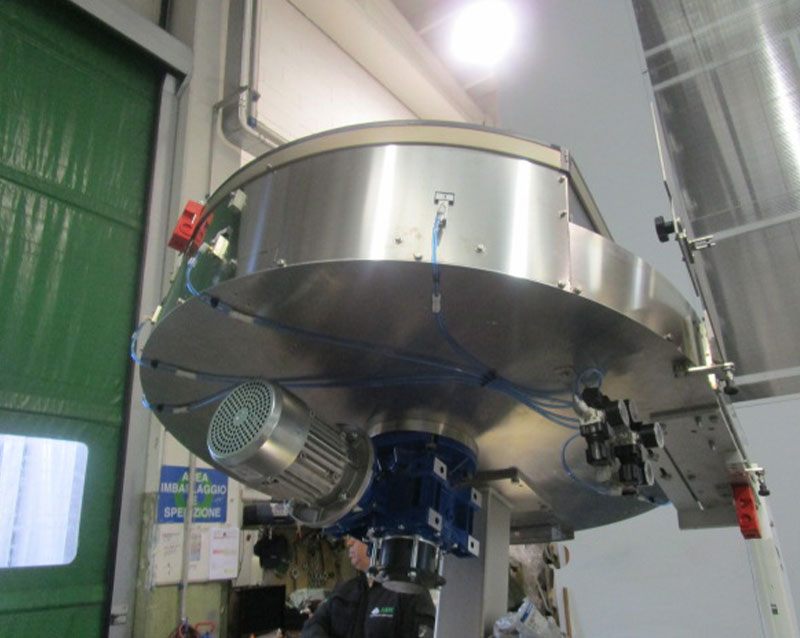

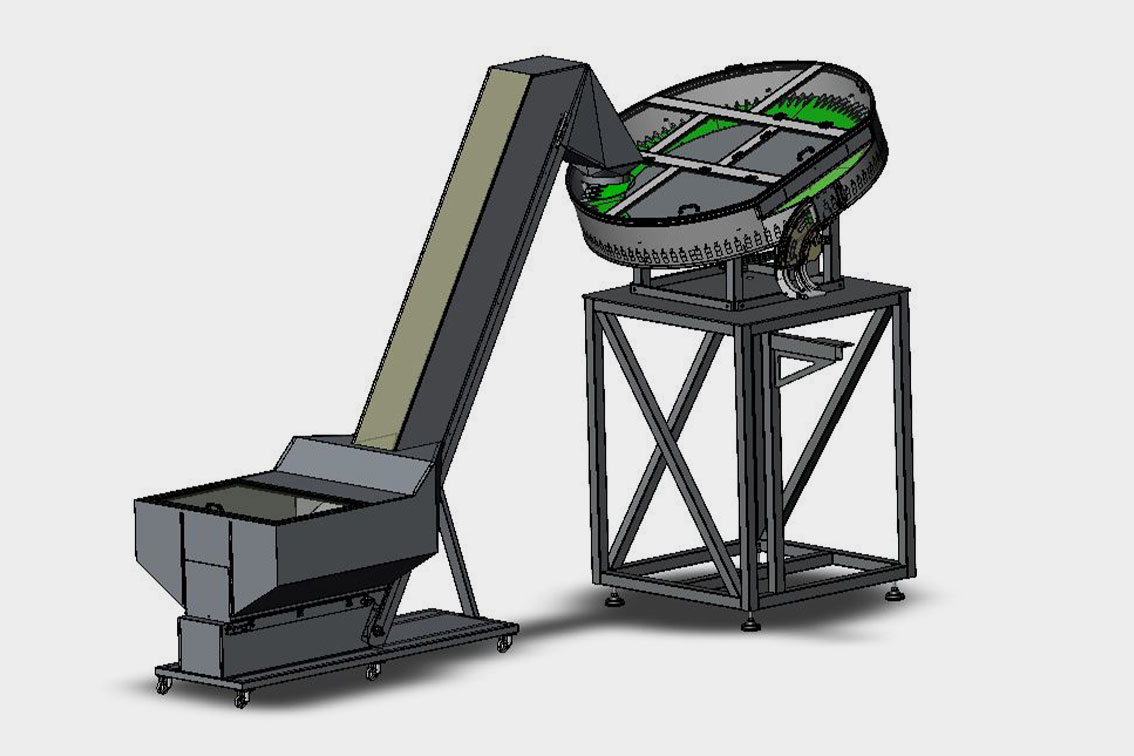

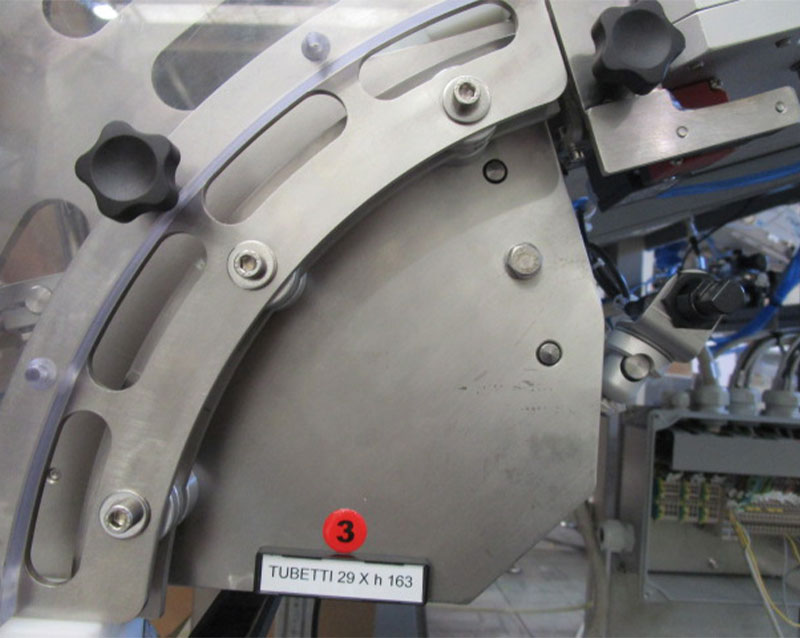

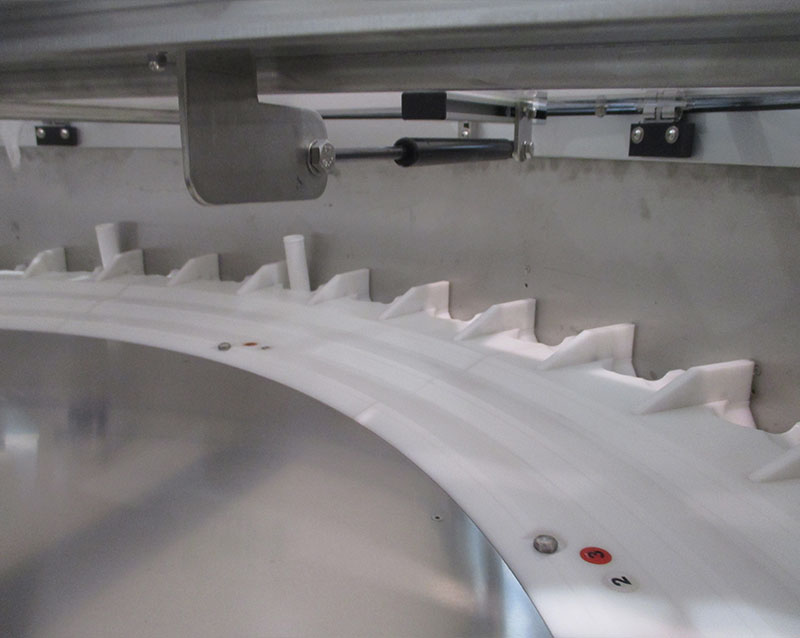

Mechanical orientator for tubes

We propose a novel orientation system for processing several tube models with the same format. Simple adjustments enable the orientator to select different models that are compatible with the dimensions. This enables the end user to reduce or even eliminate downtime due to format changes. The necessary steps are taken to prevent items getting damaged and the same machine can work on several models at high/medium speeds.

Mechanical orientator for tubes of various dimensions

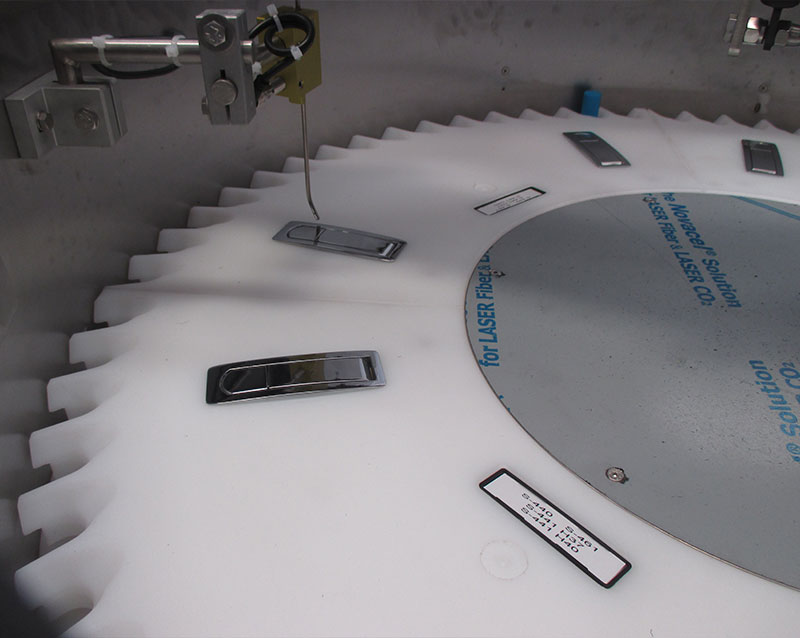

Customized system for processing caps at 400 items a minute. With the due precautions, the integrity of the items being processed by the machine is guaranteed. Customized conveying systems enable the items to be processed in a single position. The customized format changes enable different models to be processed with the same plant.

The combined loading hopper that can vary according to the required autonomy, and the plant consisting of an air channel, a support structure, noise damping protection and control panel make the machine a turnkey project.