Project Description

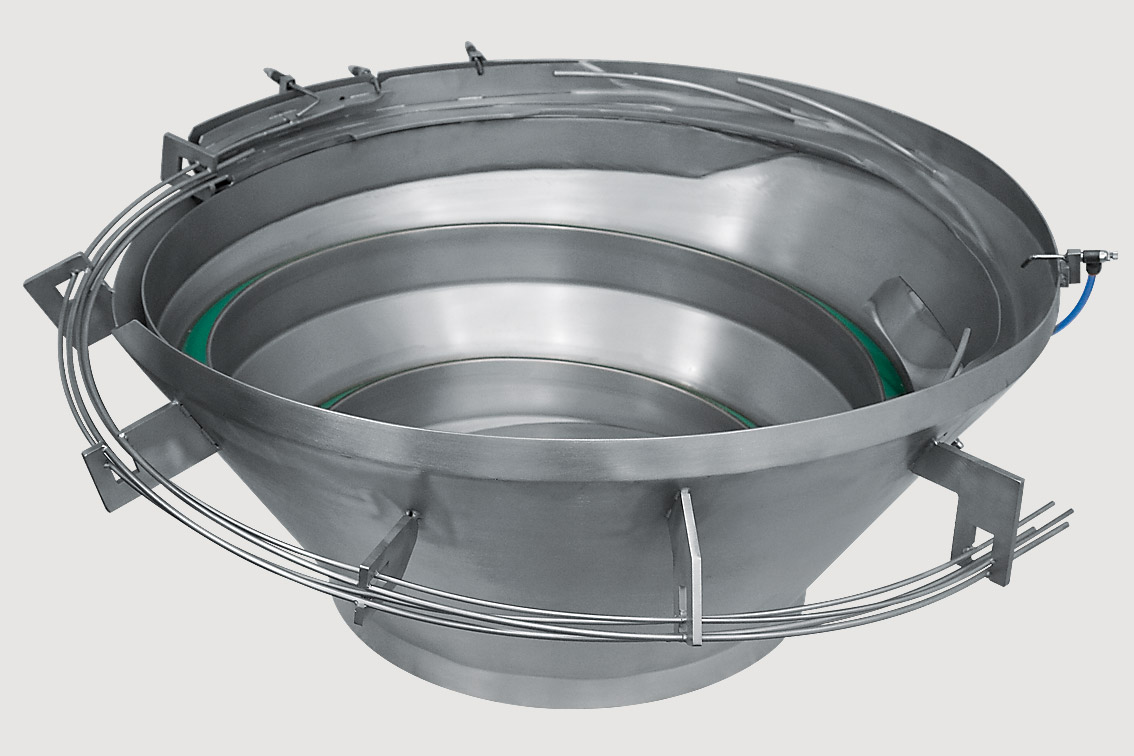

TC conical bowl feeder

This conical container (or conical bowl feeder) is suitable for a wide range of applications. Combined with a carefully designed vibratory feeder (BV), it can process both plastic (light) and metal (heavy) parts.

The design of our conical bowl feeder can be customized to suit different requirements. It can be made of AISI-304 stainless steel or, on request, of AISI-316L stainless steel.

This finish can be achieved by sandblasting or brushing, and, upon request, we can also provide the following treatments:

- Shot peening: to increase the fatigue resistance of the treated components. This is done by cold hammering the surface of the part, using a jet of spherical pellets or cylinders. By using this process on the conical bowl, it is possible to prolong its life.

- Mechanical mirror polishing: to obtain surfaces that require special brightness and shine, with homogeneous light reflection. This is obtained by using fine-grained abrasives.

- Electro-polishing: to eliminate the surface coat of a metal and reduce irregularities. It is also useful to increase the material’s resistance to corrosion. It is obtained through electrolysis.

- Passivation: to hinder the corrosion process of the conical bowl feeder, its surface is covered with a special protective film.

For any information on the conical bowl feeders for automation, or for a free quote, please contact us using the form below.

Suitable for

What are conical bowl feeders

A conical bowl feeder is an industrial automation device that is used to efficiently sort and orient small parts for further processing. These feeders are designed with a tapered, cone-shaped bowl that spins at a controlled speed. As the bowl spins, the parts are gently lifted and tilted, causing them to move along the bowl’s surface and into the desired orientation.

Typical use cases of conical bowl feeders

A common example of a typical use case for a conical bowl feeder is in the filling and packaging industry. In this application, the feeder is used to sort and orient caps with a bigger diameter then the heights, longitudinal parts, bigger caps and atomizer, spray-pumps, drop-counter used in the filling and packaging. The feeder’s cone-shaped bowl is specifically designed to accommodate the unique shape of these parts, ensuring that they are properly oriented and ready for packaging.

Conical bowl feeders are an essential piece of automation equipment for many industrial applications. They are designed to sort and orient bigger and elongated components quickly and efficiently, making them a cost-effective and time-saving solution for many manufacturers.