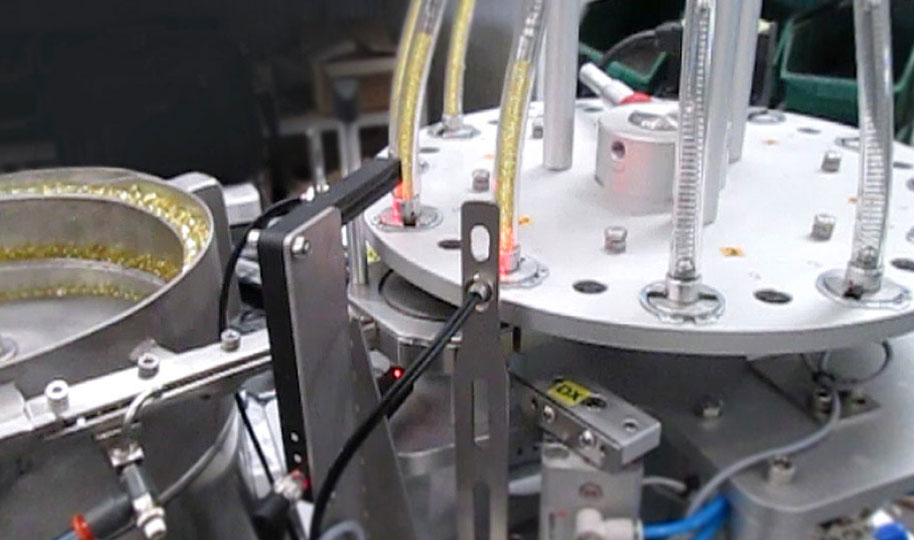

SWAROVSKI® stacker

For the automatic counting sector, we propose a feeding system for delicate even luxury items like SWAROVSKI®. The system consists of a vibrator, counting system and support structure. We have coated all the contact parts of items of this type to ensure that they do not get damaged. Our system sets the number of items to be counted.

SWAROVSKI® stacker

For the automatic counting sector, we propose a feeding system for delicate even luxury items like SWAROVSKI®. The system consists of a vibrator, counting system and support structure. We have coated all the contact parts of items of this type to ensure that they do not get damaged. Our system sets the number of items to be counted.

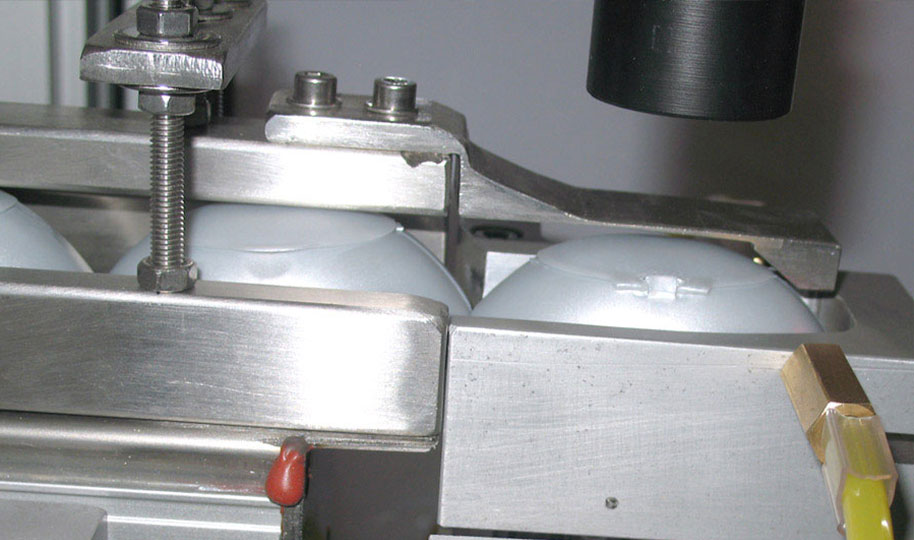

Orientation systems for BOW-SHAPED CAPS

Customized system for processing elliptical caps with particular orientation needs. This customized system is recommended for high production rates and is able to process the items whilst ensuring their integrity and orienting them in a manner that differs from the market ‘standard’.

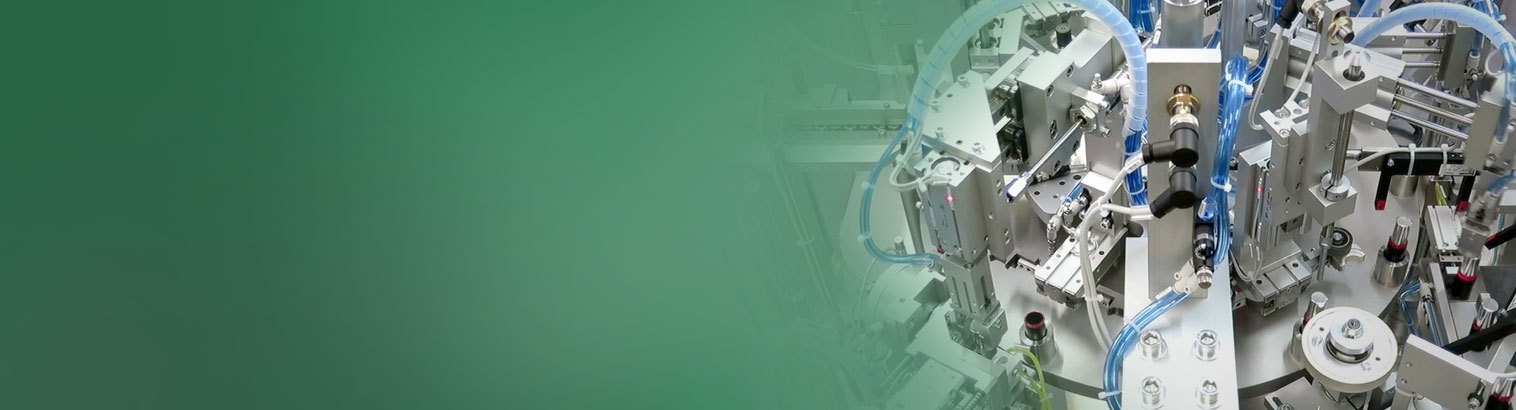

Orientation systems for TRIGGERS

System designed and engineered for customized processing of triggers of various dimensions and characteristics. The orientator diameter varies according to the dimensions and speeds required by the customer. Turnkey plant comprising a loading system, orienting system and customized conveying system that are all managed by our control panel. Several formats can be managed by changing the rapid customization.

The plant can be customized for the sector of use (pharmaceutical, chemical, etc.)

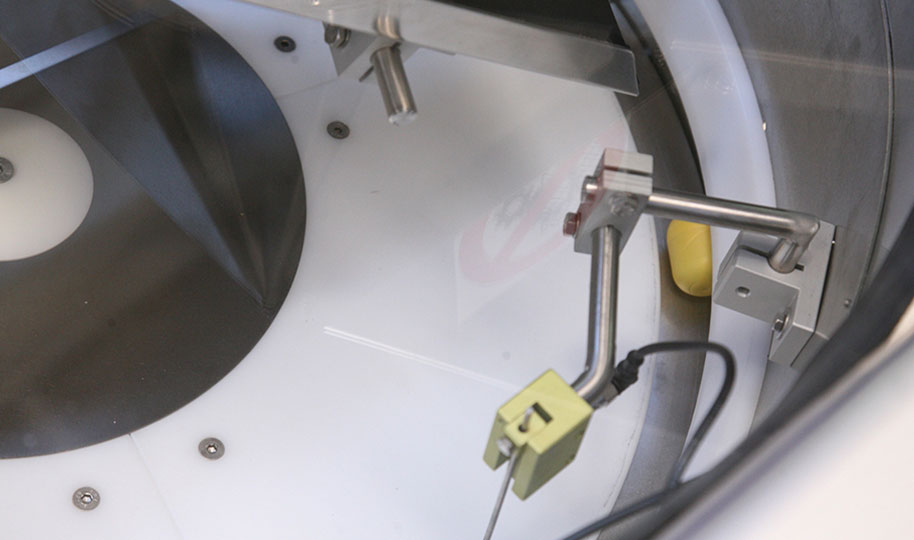

Pitched spacing system for COUNTING/QUALITY CONTROL

For the food industry, we propose a machine tending system of the customer for product counting and quality control. In this specific case, the plant has been customized to process small surprise casks for chocolate eggs.

Orientation systems for BOW-SHAPED CAPS

Customized system for processing elliptical caps with particular orientation needs. This customized system is recommended for high production rates and is able to process the items whilst ensuring their integrity and orienting them in a manner that differs from the market ‘standard’.

Orientation systems for TRIGGERS

System designed and engineered for customized processing of triggers of various dimensions and characteristics. The orientator diameter varies according to the dimensions and speeds required by the customer. Turnkey plant comprising a loading system, orienting system and customized conveying system that are all managed by our control panel. Several formats can be managed by changing the rapid customization.

The plant can be customized for the sector of use (pharmaceutical, chemical, etc.)